Unsere Studiengänge bieten beste Berufsaussichten und die Chance,

als Expert:innen wissenschaftliche Erkenntnisse für die Industrie nutzbar zu machen…

Posterpreis an Julio Alberto Perez Erviti

Auf der RESOLV-Klausurtagung in Harsewinkel hat Julio Alberto Perez Erviti von der Professur Computational Bioengineering

BCI-Absolventinnen entwickeln neues Recyclingverfahren für Phosphat

Abirtha Suthakar, Fabienne Ryll und Ronja Weidemann (v.l.) von der TU Dortmund Fakultaet Bio- und Chemieingenieurwesen (BCI) entwickeln für ihre…

Klausurtagung BCI 2024

Einmal im Jahr treffen sich die Professor*innen und das Dekanat BCI zu einer Klausurtagung um über aktuelle und zukünftig relevante Themen zu…

Die Fakultät BCI trauert um Sebastian Martin

Die Fakultät BCI trauert um Sebastian Martin, der im Alter von 26 Jahren am 17.02.2024 verstorben ist.

JCED Sonderausgabe zu Ehren von Prof. Gabriele Sadowski

Die Sonderausgabe anlässlich ihres 60. Geburtstages würdigt die Beiträge von Professor Gabi Sadowski zur Thermodynamik, insbesondere zur…

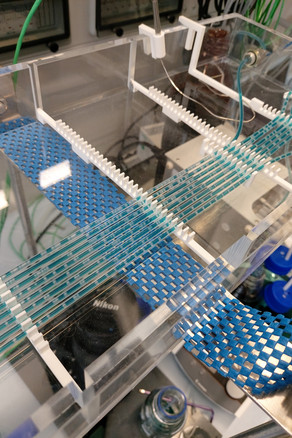

Vorstellung der Erstsemester-Projekte auf der PEP-Posterschau

Im Rahmen der Veranstaltung „Einführung in das Bio- und Chemieingenieurwesen“ erarbeiteten die Studierenden des 1. Semesters unter Betreuung der…

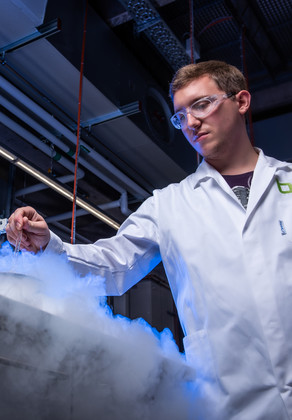

Interessierte Schüler*innen informieren sich über Studienmöglichkeiten an der Fakultät BCI

Im Rahmen der Dortmunder Hochschultage konnte in unserem Hause eine Vielzahl von Schüler*innen begrüßt werden, die sich über die Studienangebote der…

Frohes neues Jahr 2024!

Wir wünschen allen Mitarbeiter*innen, Studierenden, Kooperationspartner*innen, Alumnae sowie Freund*innen der Fakultät BCI ein frohes, erfolgreiches…

Aktuelle Veranstaltungen

Studienabschlussfeier der Fakultät

für Absolventinnen und Absolventen des Zeitraums 16.09.2023 bis 15.09.2024

Reducing the climate impact of the global petrochemical and plastic industry (Ronja Hermanns, carbon minds)

Öffentlicher Vortrag zur BCI Veranstaltung: 1,5 oder 4°C - Herausforderungen des Klimawandels

Reaching Net-Zero: Carbon Management @ BASF (Carsten Drechsler, BASF)

Öffentlicher Vortrag zur BCI Veranstaltung: 1,5 oder 4°C - Herausforderungen des Klimawandels