High throughput Simulation (HTS) of gas separation processes and the application of AI

Open new doors - High throughput Simulation (HTS) of membrane processes and the application of AI using the example of gas separation

Peter Kreis1), Leif Nett1), Markus Priske2)

1) Evonik Operations GmbH, Process Technology & Engineering

2) Evonik Fibres GmbH

Resource efficiency is a decisive factor for the success of the chemical industry. One

approach for the development of more efficient downstream processes is the early

consideration of innovative separation processes, such as membrane processes, in

process development.

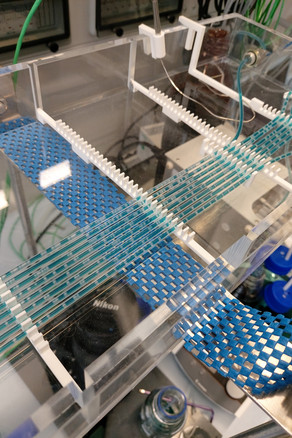

Membrane processes are increasingly applied, especially for the separation of

gaseous mixtures. Industrial examples are upgrading of technical gases (hydrogen,

helium, synthesis gas, ...), biogas and natural gas, recovery of condensable valuable

products from exhaust gases, but also CO2 capture.

Existing limitations in single-stage processes in terms of purity and yield can be

overcome by intelligently combining membrane processes into multi-stage processes.

Here, detailed/rigorous mathematical models are used for process design, which are

usually integrated into commercial process simulation software. In order to take into

account relevant influences of the operating parameters and non-idealities on the

membrane separation and thus also to determine an optimal process configuration,

very extensive simulations are necessary. This is where a method for High Throughput

Simulation (HTS) starts, in order to run the complete parameter field in a very short

time despite a combinatorial explosion in the parameter variation.

Examples of this are simple one-stage separations up to 2, 3 or 4 stage membrane

processes, as well as the application of machine learning tools to predict the relevant

parameters in (mili)seconds.